This enhanced Lean Six Sigma DMAIC process map provides execution details that structurally integrating lean and Six Sigma tools so that the right tool is used at the right time.

DMAIC methodology enhancement should be important to those desiring to benefit the most from a Lean Six Sigma process improvement deployment. The Define-Measure-Analyze-Improve-Control (DMAIC) roadmap for process enhancement should integrate both lean and Six Sigma so that the most appropriate tools is used at the right time.

DMAIC Process Map Enhancement and its Process Improvement Roadmap

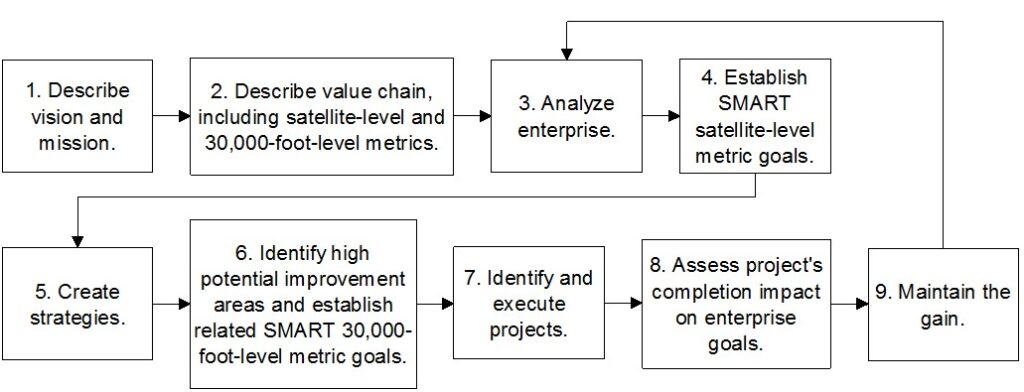

Define-Measure-Analyze-Improve-Control (DMAIC) is the process improvement project execution roadmap for Six Sigma. A more detailed, enhanced roadmap that has truly integrated Lean and Six Sigma tools is provided in the Integrated Enterprise Excellence (IEE) DMAIC roadmap for project execution, as shown in Figure 1.

In the IEE DMAIC roadmap, Lean tools are incorporated in the Measure and Improve phases. Additional drill downs are shown for the Measure phase since some of the tools that GE described in the Measure phase of the DMAIC roadmap in the 1990s are further described in these drill downs; e.g., MSA, Measurement Systems Analysis and flowcharting included in Wisdom of the Organization drill down. Lean Six Sigma Black Belt and Green Belt training has alignment to this roadmap

Figure 1

IEE DMAIC Roadmap

Some deliverables for each of the phase steps are:

- Define: Problem statement, project charter, supplier-input-process-output-customer (SIPOC)

- Measure (Plan Project and Metric): Project customer and stakeholder definition

- Measure (Baseline Project): Creation of 30,000-foot-level predictive metric

- Measure (Lean Assessment): Takt time, Little’s Law, Workflow analysis, 5 whys, value stream mapping

- Measure (MSA): Measurement systems analysis of both continuous and attribute response

- Measure (WOO): Flow charting, cause-and-effect diagram, cause-and-effect matrix, Failure Mode and Effects Analysis (FMEA)

- Analyze: Regression analysis, Analysis of Variance (ANOVA), Analysis of Means (ANOM), visual analysis

- Improve: Design of Experiments (DOE), 5S, kanban, kaizen events, changeover reduction, total productive maintenance

- Control: Control plain, error-proofing process

Two books of the Integrated Enterprise Excellence 5-book series provide the details of executing this roadmap:

- Integrated Enterprise Excellence, Volume III – Improvement Project Execution: A Management and Black Belt Guide for Going Beyond Lean Six Sigma and the Balanced Scorecard, Forrest W. Breyfogle III, Citius Publishing, 2008

- Lean Six Sigma Project Execution Guide, Forrest W. Breyfogle III, Citius Publishing, 2010

The Integrated Enterprise Excellence (IEE) integrates Lean Six Sigma process improvement with predictive scorecards and identification of strategies that lead to improvement project identification that benefit the enterprise as a whole.

IEE addresses the traditional business scorecard and process improvement issues that are described in a 1-minute video:

Additional information about DMAIC Process Map Enhancement through Integrated Enterprise Excellence (IEE)

- DMAIC Process Map Methodology Enhancement through IEE: Articles, Videos, Books

- Addressing executive challenges through wise use of DMAIC process

- Using some of the tools in DMAIC methodology enhancement to create predictive scorecards

- Use the DMAIC methodology enhancement method of predictive performance reporting throughout the organization

- Integrating business process management with Lean Six Sigma DMAIC methodology enhancement

Contact Us to set up a time to discuss with Forrest Breyfogle how your organization might gain much from an Integrated Enterprise Excellence (IEE) Business Process Management System and its enhanced DMAIC process map for executing lean Six Sigma projects.